Asia

EMEA

Our rubbers get things rolling

High-tech rubbers from LANXESS make "Green Tires" a reality

LANXESS offers the world’s broadest range of synthetic plastics. The example of butyl rubber shows the extent to which synthetic rubbers impact the development of the tire market. Although the name is unusual, it is a commonly used material – after all, almost every car-owner in the western world takes a couple of grams of this polymer for a ride each day. This is a good thing, because tubeless tires are made possible by butyl rubber – which means we don’t have to keep filling them with air every few kilometers. The reason for this is very difficult to see from the outside: it looks like most other tire rubbers. Yet it has a key distinguishing feature: it is impermeable to a number of gases – including air. For this reason, even thin sheets of this elastic material are sufficient to consign more and more conventional – and seemingly chronically broken – tubes to the museum.

In the synthetic rubber family, however, butyl rubber is actually an elder statesman: it was developed in the early 1940s. Yet long ago this substance began producing more modern off-shoots: as more and more people want tubeless radial tires for their cars, the so-called halo butyl rubbers are especially popular at the moment. These rubber raw materials can be more easily vulcanized than conventional butyl rubber. Today, 85 percent of butyl rubbers produced by LANXESS are used in tires.

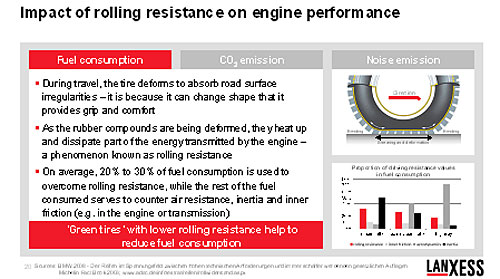

Especially with regard to the tread, all signs point to green – thanks to the so-called neodymium rubbers that are much more elastic than many other tire elastomers, rolling resistance can be lowered and fuel consumption thus reduced. Like SSBR rubbers, neodymium rubbers are a young off-shoot of an established family of materials: they belong to the family of butadiene rubbers, which account for about one quarter of global synthetic rubber production. More than two thirds of this figure is used in tires; LANXESS plays a major role in this market with the Buna® CB, Buna® VSL, Buna® SE and Taktene® brands.

- Gallery