Asia

EMEA

Lewatit® FO 36

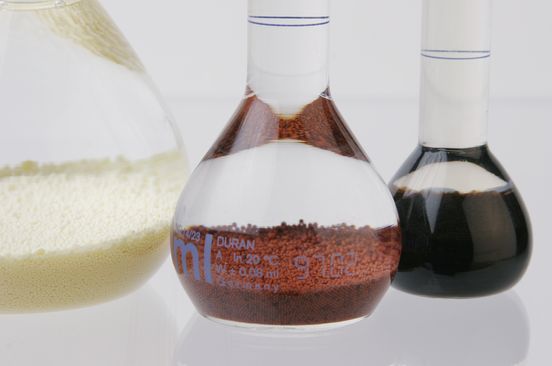

Lewatit® FO 36 is a macroporous, monodispersed, weakly basic, polystyrene-based ion exchange resin for the selective adsorption of oxoanions, such as arsenate or arsenite ions. It is doped with a nano-scale film of iron oxide covering the inner surfaces of the pores of the polymer bead. Target oxoanions are bonded by a specific, reversible reaction involving hydroxy-groups on the iron oxide surface.

Lewatit® FO 36 is especially suitable for use in the following applications:

In the purification of potable water arsenic can be removed down to rest concentrations significantly lower than 10 µ g/l which is the maximum contaminant level set in several countries. Lewatit® FO 36 is also capable of adsorbing other species such as HPO 4 2-, HSbO4 2-, SCN- etc.

Business Unit

Liquid Purification Technologies

Properties and benefits

- Arsenic removal from drinking water

- Arsenic removal from ground water (ground water remediation)

- Arsenic removal from process solutions even in presence of high contents of neutral salts .

Areas of Applications

- Potable Water Treatment

- Industrial Water Treatment

- Waste Water Treatment

How to use the product

When using Lewatit® FO 36 to treat potable water, special care should be paid at the onset. Please refer to the recommended start-up-conditions contained in this data sheet.

After pre-treatment as per instructions, Lewatit® FO 36 is in compliance with the European Resolution ResAP (2004)3

Synonyms

Ion Exchange Resin

2010-11-26

LANXESS at Pollutec 2010,<br>November 30 to December 3, Lyon,<br> Hall 8, Stand H 277

Lewatit ion exchange resins today for the water problems of tomorrow

Specialty chemicals group LANXESS will showcase its high-performance range of Lewatit ion exchange resins at Pollutec 2010 in Lyon from November 30 to December 3. The focus of the group’s presentation at this international trade fair for water, air, noise and waste technology is on products for wastewater treatment. The Ion Exchange Resins business unit will share its stand at the fair with Ocene, its local distribution partner in France.

Particular attention will center on the modified hybrid adsorber Lewatit FO 36 for selective arsenic removal from drinking water and Lewatit MonoPlus TP 207. This chelating resin is used, for example, for the removal of heavy metals in process water and wastewater treatment. This premium product has already proved its worth in practice. For example, a French metal industry supplier, whose wastewater exhibited excessive levels of nickel, was spared having to pay a fine by applying Lewatit MonoPlus TP 207 and opting for technical support from LANXESS experts. This action reduced the concentration of nickel to a safe level well below the specified legal limit.

LANXESS produces ion exchange resins and special adsorber resins for around 500 different applications. These products play an important role in alleviating a wide range of water problems. The use of ion exchange resins offers excellent potential for the future, particularly in light of global developments such as drinking water shortages and rising energy demand. Jean-Marc Vesselle, head of the Ion Exchange Resins business unit, said: “We are using our many years of experience and targeted investments to meet the challenges thrown up by growing urbanization. Lewatit is an integrated solution concept comprising products and application engineering advice. Our sales and production sites are ideally positioned to supply fast-growing heavily populated areas. Strategic investments in Jhagadia and in Bitterfeld are enabling us to meet the rising demand for ion exchange resins and membrane filtration products.” In total, the group invests EUR 50 million at its Jhagadia site and EUR 30 million to develop and produce membrane filtration technology at its site in Bitterfeld. This new plant is scheduled to be taken into operation for a pilot and development phase at the end of this year. According to current planning, the first products should be launched on the market in 2011.

In the future, the new ion exchange resin facility in Jhagadia will supplement the two production sites in Germany. The new plant in Gujarat in Western India will be officially opened on December 2, 2010. It will have an annual capacity of 35,000 metric tons and be the most state-of-the-art facility of its kind in Asia. The grades manufactured there are earmarked in particular for the production of ultrapure water for the pharmaceutical industry, semiconductor production, industrial water treatment, the food industry and energy generation. “Our new plant in Jhagadia is being taken into operation at just the right time, because it perfectly complements the existing production network in Leverkusen und Bitterfeld,” said Vesselle to underline the importance of the prompt completion of the project.

The Lewatit product range is ideal for very many areas of application in water and wastewater treatment. Important parameters for plant operators include lower chemical and energy consumption, a high operating capacity and a reduction in wastewater. Moreover, the cost of investment in new plants is cut by reducing container dimensions and optimizing resin volumes. Detailed information on LANXESS’ ion exchange resin range can be found at www.lewatit.com.

The Ion Exchange Resins business unit is part of LANXESS’ Performance Chemicals segment, which achieved total sales of EUR 1,530 million in 2009.

LANXESS is a leading specialty chemicals company with sales of EUR 5.06 billion in 2009 and currently around 14,500 employees in 23 countries. The company is represented at 42 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals.

- Gallery