Asia

EMEA

Lewatit® FO 36

Lewatit® FO 36 is a macroporous, monodispersed, weakly basic, polystyrene-based ion exchange resin for the selective adsorption of oxoanions, such as arsenate or arsenite ions. It is doped with a nano-scale film of iron oxide covering the inner surfaces of the pores of the polymer bead. Target oxoanions are bonded by a specific, reversible reaction involving hydroxy-groups on the iron oxide surface.

Lewatit® FO 36 is especially suitable for use in the following applications:

In the purification of potable water arsenic can be removed down to rest concentrations significantly lower than 10 µ g/l which is the maximum contaminant level set in several countries. Lewatit® FO 36 is also capable of adsorbing other species such as HPO 4 2-, HSbO4 2-, SCN- etc.

Business Unit

Liquid Purification Technologies

Properties and benefits

- Arsenic removal from drinking water

- Arsenic removal from ground water (ground water remediation)

- Arsenic removal from process solutions even in presence of high contents of neutral salts .

Areas of Applications

- Potable Water Treatment

- Industrial Water Treatment

- Waste Water Treatment

How to use the product

When using Lewatit® FO 36 to treat potable water, special care should be paid at the onset. Please refer to the recommended start-up-conditions contained in this data sheet.

After pre-treatment as per instructions, Lewatit® FO 36 is in compliance with the European Resolution ResAP (2004)3

Synonyms

Ion Exchange Resin

2013-04-12

New finely dispersed ion exchange resins from LANXESS

Smaller, faster, more stable

Small bead radius for more efficient chloralkali brine treatment

Specialty chemicals company LANXESS has expanded its proven Lewatit line of ion exchange resins to include a new generation of finely dispersed grades. These newly developed ion exchange resins with small bead radius, their properties and applications were the subject of a presentation by Dr. Stefan Neumann, head of Applications development in LANXESS’ Liquid Purification Technology business unit, at this year's Technology Symposium held by the Chlorine Institute in Houston, Texas, on April 8, 2013.

Monodisperse, macroporous chelating resins of this kind significantly enhance the efficiency of brine treatment for chloralkali electrolysis based on membrane technology. Furthermore, they effectively help to prevent damage to the increasingly sensitive, latest-generation membranes.

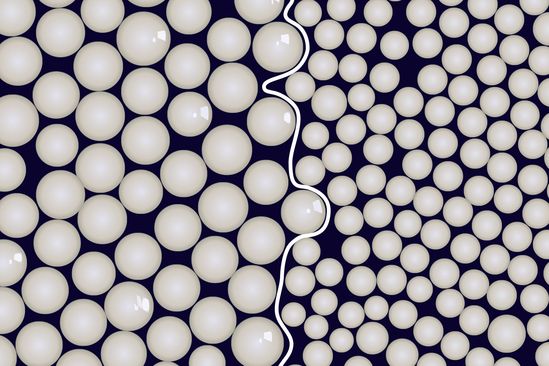

The critical difference between the new resin grades and those sold previously is the bead diameter. In the monodisperse small (MDS) grades, such as Lewatit MDS TP 208, the diameter is only 390 micrometers, or 40 percent smaller than that of the likewise monodisperse grade Lewatit MonoPlus TP 208. This size difference translates into roughly twice the bead surface per unit of volume. As a result of this difference, the MDS grades display improved kinetics, a higher degree of regeneration and a significantly increased total and operating capacity specifically for alkaline earth cations. At the same time, they have optimal mechanical and osmotic stability.

Barium and strontium ions are removed from the brine with particular efficiency. This is a remarkable characteristic in view of the low selectivity of many other resins and their slow exchange kinetics. The chelating resins also bind the lighter elements in the alkaline earth group, such as calcium and magnesium. Their improved leakage is an important advantage, because the reduced leakage helps to increase the service life of the electrolysis membranes. In this respect, the MDS resins have anticipated the continuous advancements in membrane development, because the concentration tolerances for alkaline earth ions will likely decrease further in the future.

Numerous economic advantages

Resins in the MDS line give electrolysis operators a number of economic advantages, most of which are based on the following effects:

- Longer lifetime of the membranes and the resin,

- Lower operating costs as a result of lower regenerating agent requirements and less waste water,

- Longer cycle times for the resin, and

- Higher throughput in brine production.

The new resin grades have already been used on an industrial scale with good success in Germany.

“However, we must keep in mind that the MDS resins, on account of their higher bulk density, display more of a pressure drop and greater filter bed expansion than the standard grades. What is more, they react more sensitively to suspended solids,” Neumann explains.

In addition to chloralkali electrolysis with membrane technology, Neumann mentioned other potential fields of application for the MDS resins, including the ultra-high purification of brine for use in membrane cells of the latest generation. However, the outstanding product characteristics of the MDS TP resins can also be exploited to good advantage in other applications.

The Liquid Purification Technologies business unit is part of LANXESS' Performance Chemicals segment, which recorded sales of EUR 2.2 billion in fiscal 2012.

LANXESS is a leading specialty chemicals company with sales of EUR 9.1 billion in 2012 and roughly 17,200 employees in 31 countries. The company is currently represented at 49 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of plastics, rubber, intermediates and specialty chemicals. LANXESS is a member of the leading sustainability indices Dow Jones Sustainability Index (DJSI) World and FTSE4Good as well as the Carbon Disclosure Leadership Index (CDLI).

- Gallery