Asia

EMEA

Lewatit® FO 36

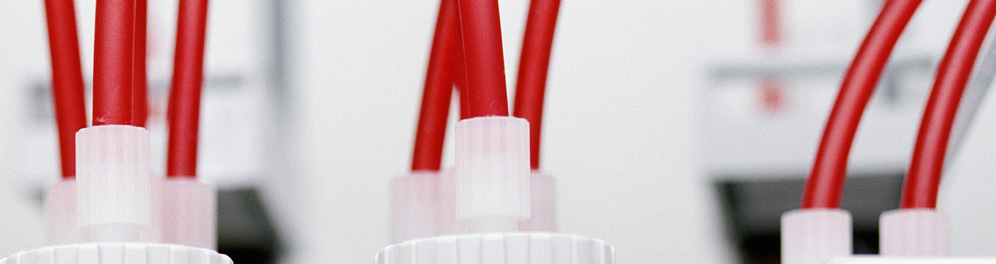

Lewatit® FO 36 is a macroporous, monodispersed, weakly basic, polystyrene-based ion exchange resin for the selective adsorption of oxoanions, such as arsenate or arsenite ions. It is doped with a nano-scale film of iron oxide covering the inner surfaces of the pores of the polymer bead. Target oxoanions are bonded by a specific, reversible reaction involving hydroxy-groups on the iron oxide surface.

Lewatit® FO 36 is especially suitable for use in the following applications:

In the purification of potable water arsenic can be removed down to rest concentrations significantly lower than 10 µ g/l which is the maximum contaminant level set in several countries. Lewatit® FO 36 is also capable of adsorbing other species such as HPO 4 2-, HSbO4 2-, SCN- etc.

Business Unit

Liquid Purification Technologies

Properties and benefits

- Arsenic removal from drinking water

- Arsenic removal from ground water (ground water remediation)

- Arsenic removal from process solutions even in presence of high contents of neutral salts .

Areas of Applications

- Potable Water Treatment

- Industrial Water Treatment

- Waste Water Treatment

How to use the product

When using Lewatit® FO 36 to treat potable water, special care should be paid at the onset. Please refer to the recommended start-up-conditions contained in this data sheet.

After pre-treatment as per instructions, Lewatit® FO 36 is in compliance with the European Resolution ResAP (2004)3

Synonyms

Ion Exchange Resin

2018-07-09

LANXESS showcases innovative and enhanced technologies for water treatment at the Singapore International Water Week 2018

Singapore, July 9, 2018 – Specialty chemicals company LANXESS is showcasing its process, technology leadership, and innovations in water treatment and purification at this year’s Singapore International Water Week exhibition from 9th to 11th July.

At this biennial event, LANXESS is exhibiting its latest technologies in combined reverse osmosis (RO) and ion exchange (IX) processes that offer a wide range of solutions to treat water to the desired standard. In addition, LANXESS is debuting, for the first time in Singapore, its new Lewabrane Ultra Low Pressure (ULP) RO elements, an expansion of its extensive range of membrane elements for reverse osmosis. Recognising the importance of user-friendly technology, LANXESS has also released a new 2.0 version LewaPlus software for designing water treatment systems, which it will be showcasing at SIWW this year.

Innovative solutions to combat water scarcity

Global warming, droughts, water pollution and erratic climate change have led to rising attention on the issue of water scarcity globally. As water is becoming an increasingly valuable resource, innovative technologies need to surface to optimise wastewater treatment, and use water efficiently. Through combining two different water treatment technologies – ion exchange (IX) and reverse osmosis (RO), LANXESS provides complete solutions to the water challenges in many countries such as wastewater treatment, water reclamation and seawater desalination.

There are numerous examples from the municipal and industrial sector show how ion exchange resins (IX) and reverse osmosis (RO) membranes complement one another to achieve optimal results in water treatment. Especially for minimal liquid discharge processes (MLD) combined solutions are necessary to find a tailor made approach to reuse or recycle water in processes. In such cases IX can be used as pre-treatment to remove hardness or organics to increase the production yield of the following RO process, or IX can be used to polish the RO permeate to up to ultrapure water quality.

Range of services for water treatment further expanded by ultrafiltration (UF)

LANXESS adds ultrafiltration (UF) to the existing range of water-treatment technologies through a cooperation agreement with the French company Polymem SA, Toulouse. LANXESS will commence worldwide distribution of the Gigamem ultrafiltration modules range from Polymem featuring Neophil hollow fiber membranes. “We are gaining a product portfolio that ideally complements our ion exchange resins and reverse osmosis membrane elements for water treatment. After all, around one third of all newly built reverse osmosis plants have upstream ultrafiltration – and the trend is rising. This results in valuable synergy effects,” says Jean-Marc Vesselle, Head of LANXESS’s BU Liquid Purification Technologies. Ultrafiltration will soon be integrated as a new module in LANXESS’s LewaPlus design software.

Improving User Experience

LANXESS has made further enhancements to its LewaPlus software, which is a free, comprehensive platform for designing water treatment systems with ion exchange resin (IX) and reverse osmosis (RO) membrane systems. This enhanced software has a high degree of design flexibility, which will allow users to have the ability to combine per drag and drop different technologies in one design and show all selected modules in a combined PDF report. In addition, the new product finder function will allow LewaPlus 2.0 users to identify which Lewatit and Lewabrane quality products they can use to replace the conventional elements to upgrade their plans. Numerous modules are available for the calculation of every step of the water treatment process. As a result, users can precisely plan important factors such as operating costs, power consumption, and water quality. One module can even be used to model a CCRO system (closed circuit reverse osmosis). This helps to enhance the ecobalance of water treatment through the use of either ZLD (zero liquid discharge) or MLD (minimal liquid discharge) treatment processes. Visitors to SIWW 2018 can experience the more user-friendly version LewaPlus 2.0 in action.

Eliminating trace elements cost-efficiently at low operating pressures

LANXESS also expanded its portfolio of Lewabrane RO membrane elements by ultra-low pressure (ULP) types. The product designation “ULP” stands for “Ultra Low Pressure,” because the advantage of these membranes is their ability to remove such organic compounds almost entirely even at low operating pressures. The new ULP products are recommended for applications in which a high flow rate, moderate salt rejection and low power consumption are the primary design parameters. Fields of application therefore are the cost-efficient filtration of drinking water and high-tech wastewater treatment.

Commitment to maintaining product quality and reliability

All products are compliant with German standards certified by international organisations to showcase LANXESS’ commitment in ensuring product safety, quality and reliability for all users and the environment. “Complemented by comprehensive customer service and technical support, we help our customers handle our products in a safe and environmentally responsible way, and at the same time also require our suppliers and service providers to demonstrate a similar sense of responsibility, so as to cultivate trust with our customers through an open and respectful communication,” said Tony Yang, Vice President of APAC, Liquid Purification Technologies business unit, LANXESS, “The increasing complexity, digitisation and continual change often results in challenges such as quality control. We place considerable emphasis on ensuring that our products meet the highest German and international production and quality standards.”

LANXESS is present at basement 2, booth B2-M20, the Water Convention at the Singapore International Water Week from 9 to 11 July 2018 at the Marina Bay Sands Expo and Convention Centre, Singapore. For more information on LANXESS, please visit, www.lanxess.sg

About LANXESS

LANXESS is a leading specialty chemicals company with sales of EUR 9.7 billion in 2017 and about 19,200 employees in 25 countries. The company is currently represented at 74 production sites worldwide. The core business of LANXESS is the development, manufacturing and marketing of chemical intermediates, additives, specialty chemicals and plastics. Through ARLANXEO, the joint venture with Saudi Aramco, LANXESS is also a leading supplier of synthetic rubber. LANXESS is listed in the leading sustainability indices Dow Jones Sustainability Index (DJSI World and Europe) and FTSE4Good.

Forward-Looking Statements

This company release contains certain forward-looking statements, including assumptions, opinions, expectations and views of the company or cited from third party sources. Various known and unknown risks, uncertainties and other factors could cause the actual results, financial position, development or performance of LANXESS AG to differ materially from the estimations expressed or implied herein. LANXESS AG does not guarantee that the assumptions underlying such forward-looking statements are free from errors nor does it accept any responsibility for the future accuracy of the opinions expressed in this presentation or the actual occurrence of the forecast developments. No representation or warranty (expressed or implied) is made as to, and no reliance should be placed on, any information, estimates, targets and opinions, contained herein, and no liability whatsoever is accepted as to any errors, omissions or misstatements contained herein, and accordingly, no representative of LANXESS AG or any of its affiliated companies or any of such person's officers, directors or employees accept any liability whatsoever arising directly or indirectly from the use of this document.